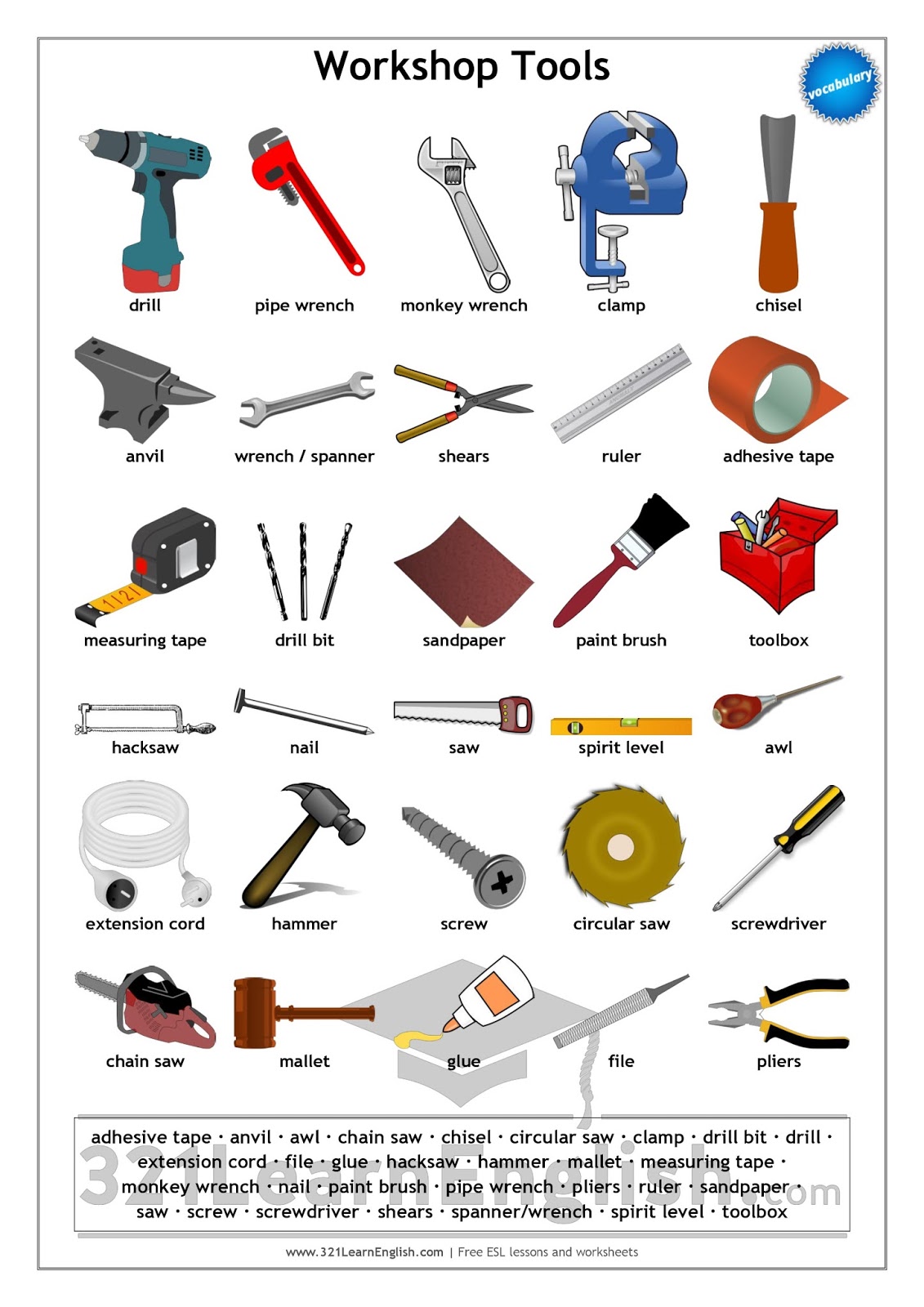

Study Of Different Types Of Hand Tools Used In Workshop

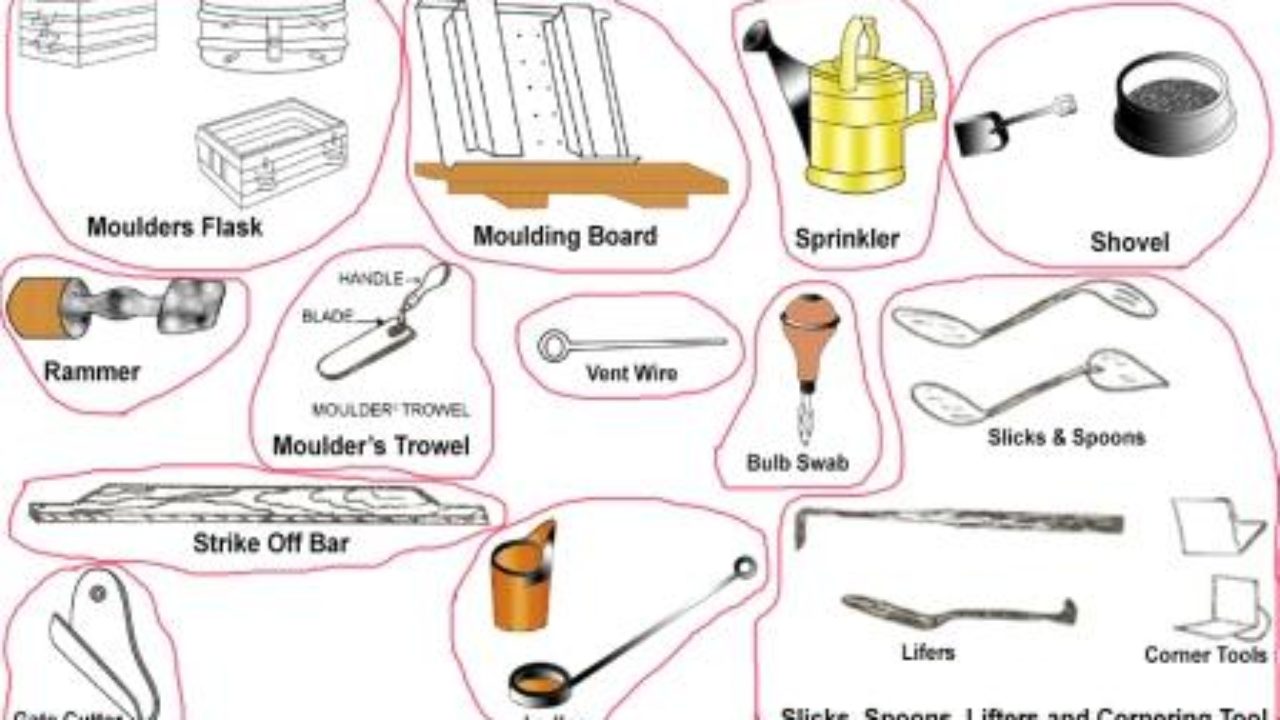

Remove sharp edges finish fillets and other interior surfaces Fig124Sharp cutting teeth are provided on its surface for the purpose.

Study of different types of hand tools used in workshop. These are mechanical tools such as drills hand cutters and dremels. Curriculum for House Wiring Study demonstration and identification of common electrical materials such as wires cables switches fuses ceiling roses PVC Conduits PVC Channels and allied items tools along with electrical instruments such as voltmeter ammeter and multimete Study of electrical safety measures and demonstration about use of protective devices such as fuses MCBs. The ideal type and model of a power tool is unique to each carpenter but generally all of them will possess the following in their work environment.

However there are some branches of cold metal work such as sheet-iron work and coppersmithing that are not usually includ-ed in machine shop work. Comprised of a twist drill surrounded by a large circular tube with a saw teeth. Their uses general characteristics attachments and safety and operating features are outlined.

They are used to hold all types of components between jaws Fixed Jaw and Movable Jaw. Introduction to sheet metal shop use of hand tools and ac cessories eg. Holding tools are also known as Work Holding devices in the Fitting workshop.

Farm road jacks are an ideal workshop tool used. No place is this more important than in the machine shop. It is a hand operated tool used to bore small holes for starting a.

To become skilled with these power tools and hand tools you must use them. Allow for larger through-holes to be cut. Slideshare uses cookies to improve functionality and performance and to provide you with relevant advertising.

The Various Work holding devices are. Portable Electric Drill 3. This file is exclusively used in wood work.