How To Make A Parting Tool Holder

I needed a parting tool that would give a little so I based my design on designs I found on the internet.

How to make a parting tool holder. Facingturning holder but holds the parting blade inverted. Successful chip control Cutting tools featuring over- and under-coolant delivered with high precision means you can control both chips and temperature for highly productive and problem-free parting and grooving. For small part machining use an insert with the smallest width and sharpest cutting edges.

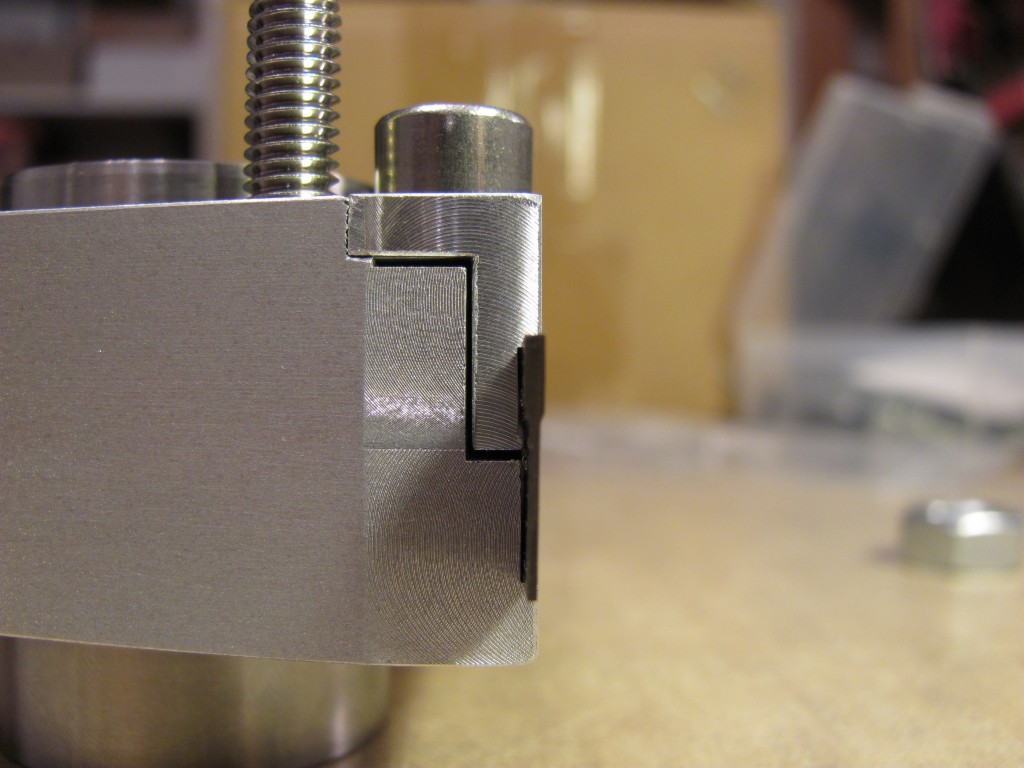

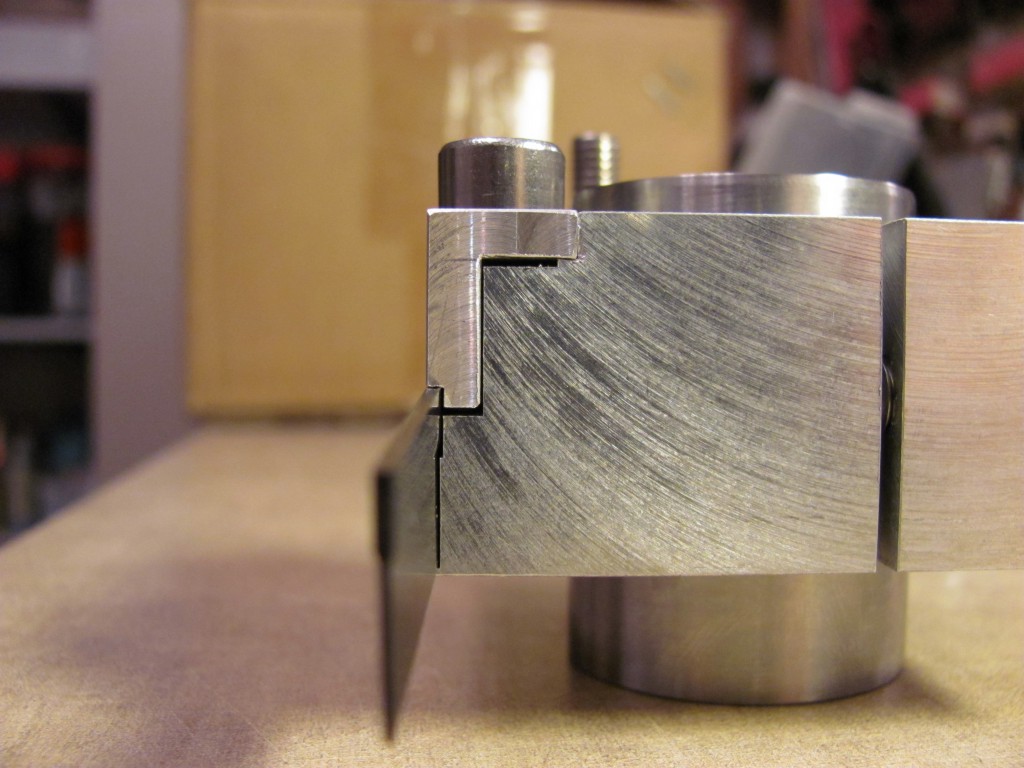

The problem of snatching with HSS parting blades. Leave one side with no slot. Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting.

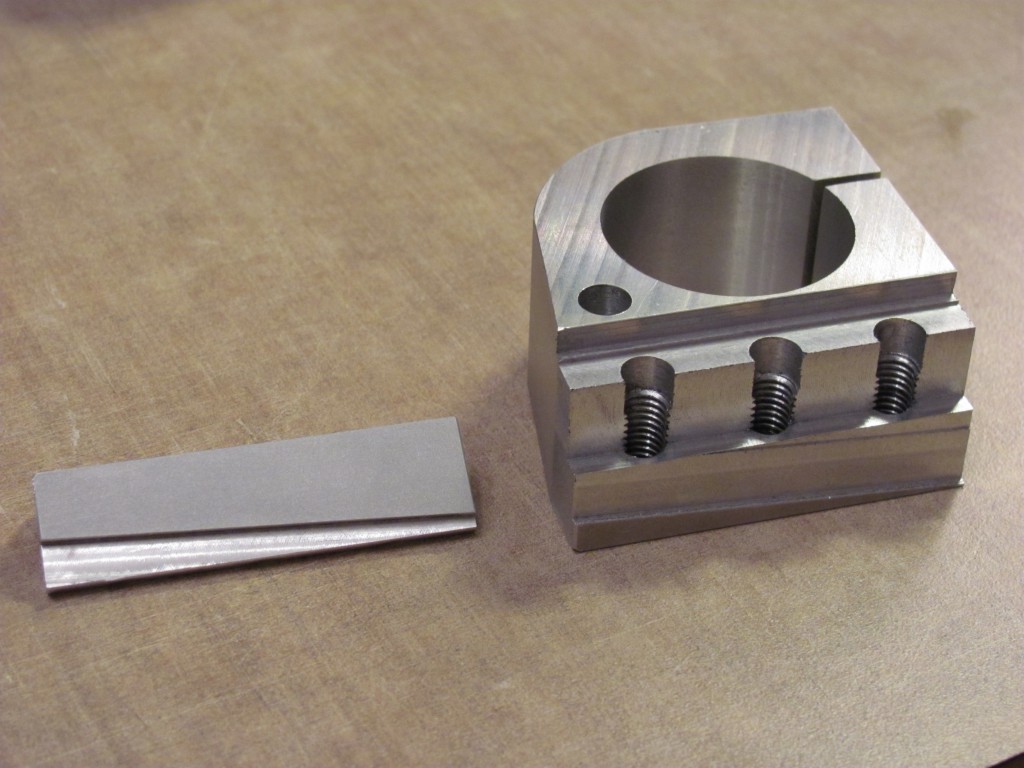

I had a short production run I needed to finish and part of the process required a small groove at the end of the piece. Repeat for 2 of the other sides. Open out to 1 dia.

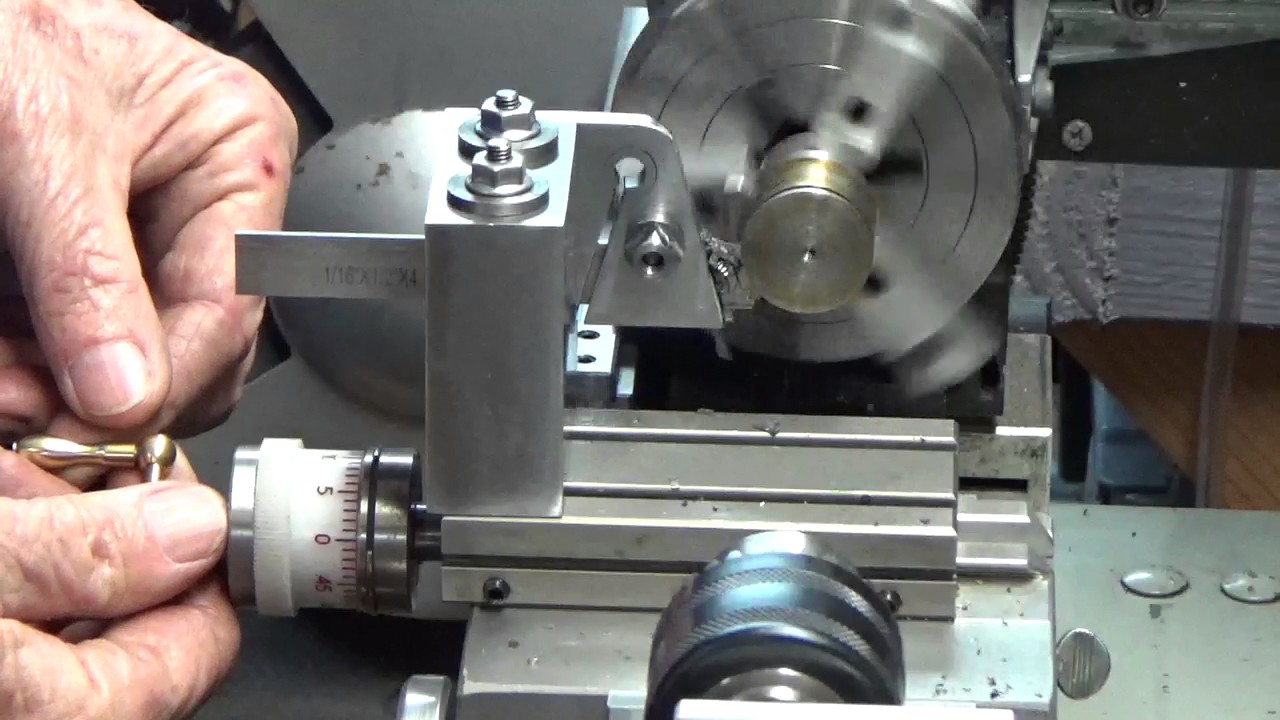

All parting has to be done with the cutter at right angles to the workpiece. No matter what holder I make it still has to be adjustable so I could center the blade. Rigidity is extremely important.

C any other designs that basically does the same thing like parting from the opposite side of the spindleetc. How to Make a Parting Tool From A Sawzall Blade. Set up in the four jaw chuck with the front wedge hole running true center and drill out to just under 34 bore to 34.

Use a master square to set the tool holder square with the lathe chuck and tighten the nut to lock the tool holder in place. Remove from chuck and drill and tap top holes. Now lock the half nut in the engaged position to keep the carriage from moving during the parting cut.