Types Of Holding Tools In Workshop

When the vice handle is turned in a clockwise direction the moving jaw forces the work against the fixed jaw.

Types of holding tools in workshop. 90 minutes to 3 hours. The specimens were taken and that you will see in the engineering workshop. Friction-free unlike hammers and lever bars these hydraulic wedges limit any damage to the joints.

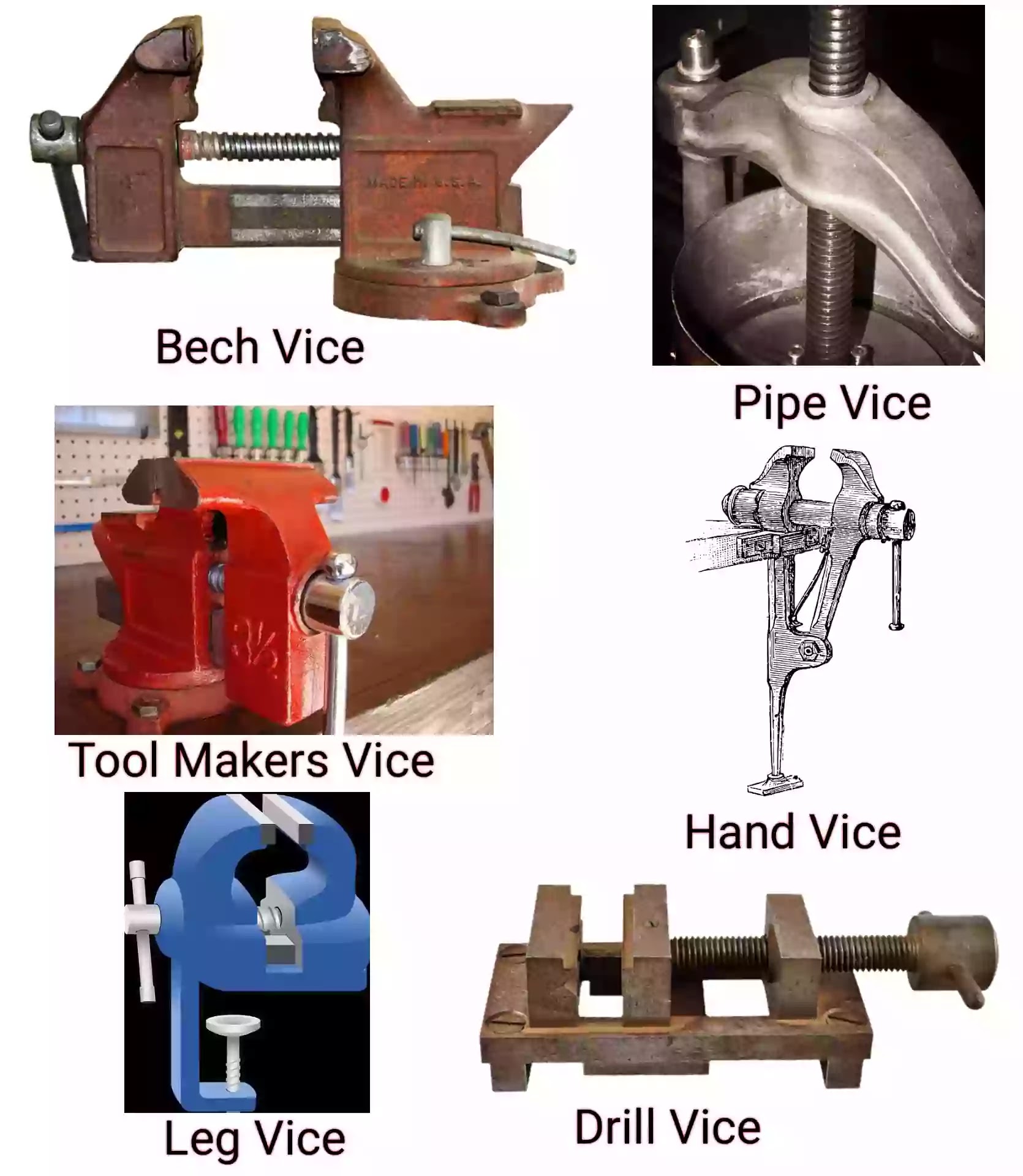

At this length a workshop can begin to address ideas and concepts in some depth and teach some skills. Bench Vice A bench vice figure 20 is the device for holding the workpiece where most hand processes to be carried out. Holding tools are also known as Work Holding devices in the Fitting workshop.

Marking Tools are used to mark any dimensions on the surface of a workpiece. Marking tools in workshop are Surface GaugeSurface PlateMarking TableScriberPrick PunchCenter PunchDividerTrammelBevel Square. Hand Tools for Workshop 5a.

A4 Machinist vise is a work holding tool for machining activity. Above is a picture that displays an example of me using this tool. The vises provide the quickest and most efficient set up method for parallel work.

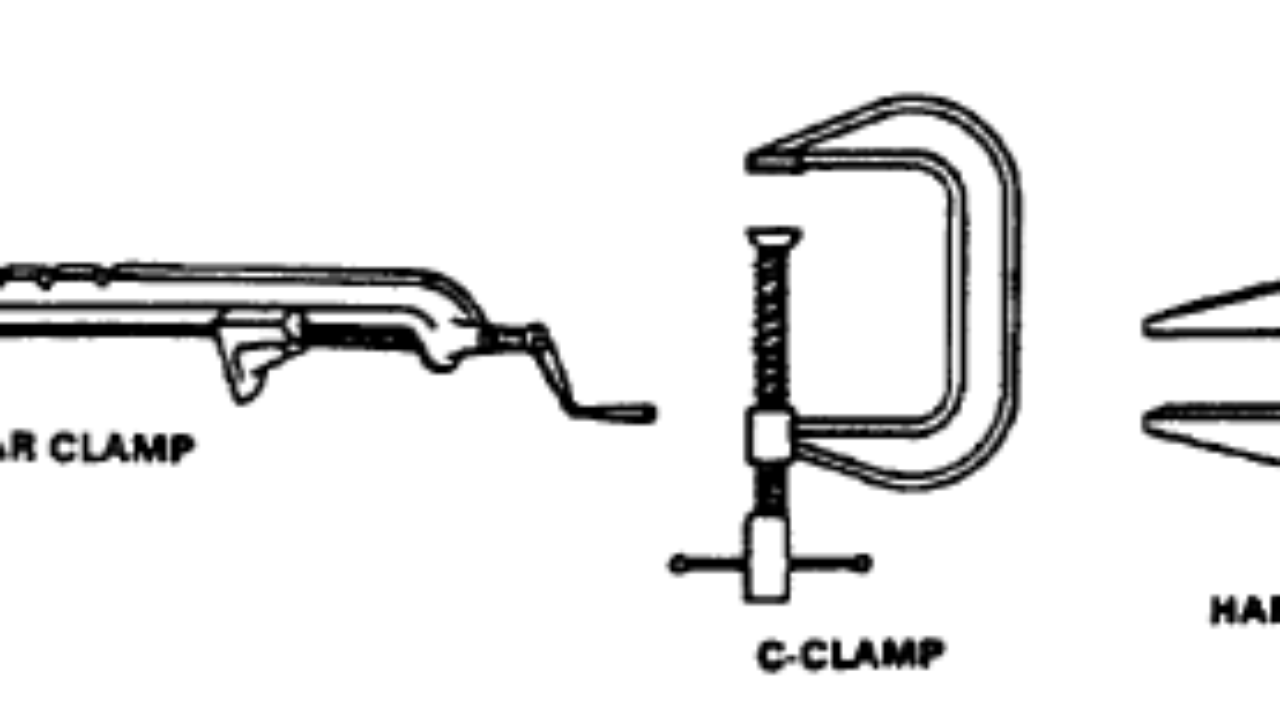

Vice is a job holding tools and types of vices used in workshop are Bench VicePipe ViceTool Makers ViceHand ViceLeg ViceDrill VicePin Vice. They are fixed in a die stock for holding and adjusting the die gap. Its uses may seem simple limited to drilling holes and inserting screws or fasteners but the drill is backed by a plethora of attachments and drill bits as well as settings for speed power and torque.

This type of workshop is more than long enough for participants to get bored or overwhelmed. Center Punch The Detailed Explanation of Marking Tools was HERE 3MEASURING TOOLS Used in Fitting. A6 Vise Grip is a tool used to grip the stock tightly enough to hold the object.