How To Sharpen Carbide Metal Lathe Tools

At present the commonly used grinding wheels are alumina and silicon carbide.

How to sharpen carbide metal lathe tools. I talk about some techniques I u. It takes a special grinding wheel made of silicon carbide abrasive When I was an apprentice that is all the shop had and we used a lot of brazed on tools in the shop. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with.

Apply layout fluid to the top surface and allow it to try completely. They require a dimond stone because its the only material hard enough to properly sharpen carbide. With steel you can use 10-20 degrees but never try to use a tool ground for steel on brass.

Assuming youre talking about brazed carbide tools the best way is with a high speed wet diamond wheel mounted on a machine with a table that tilts to establish front and side relief. Lathe tool sharpening is important to making smooth consistent cuts. Everyone knows that the hardness of cemented carbide is very high.

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. This video shows how to sharpen carbide cutting bits. Ad At Surplex you will find used machinery and industry equipment at best prices.

Without sharpening your machining. How to sharpen lathe cutting tool first of all we must choose the right grinding wheel. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner.

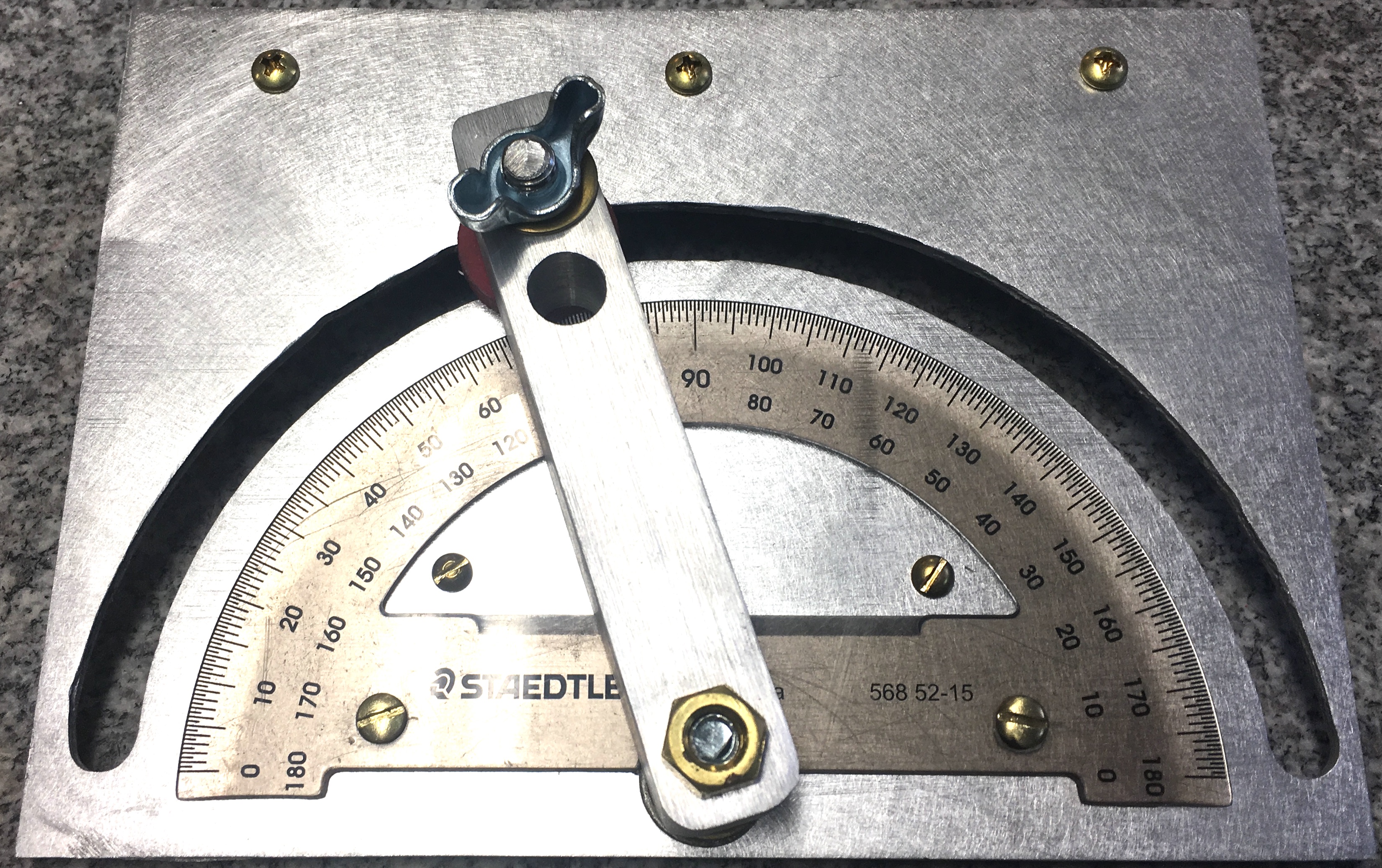

When you sharpen a lathe tool bit youre really re-drawing a number of critical angles. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. Positive rake will make your tools free cutting reducing deflection and power requirements.