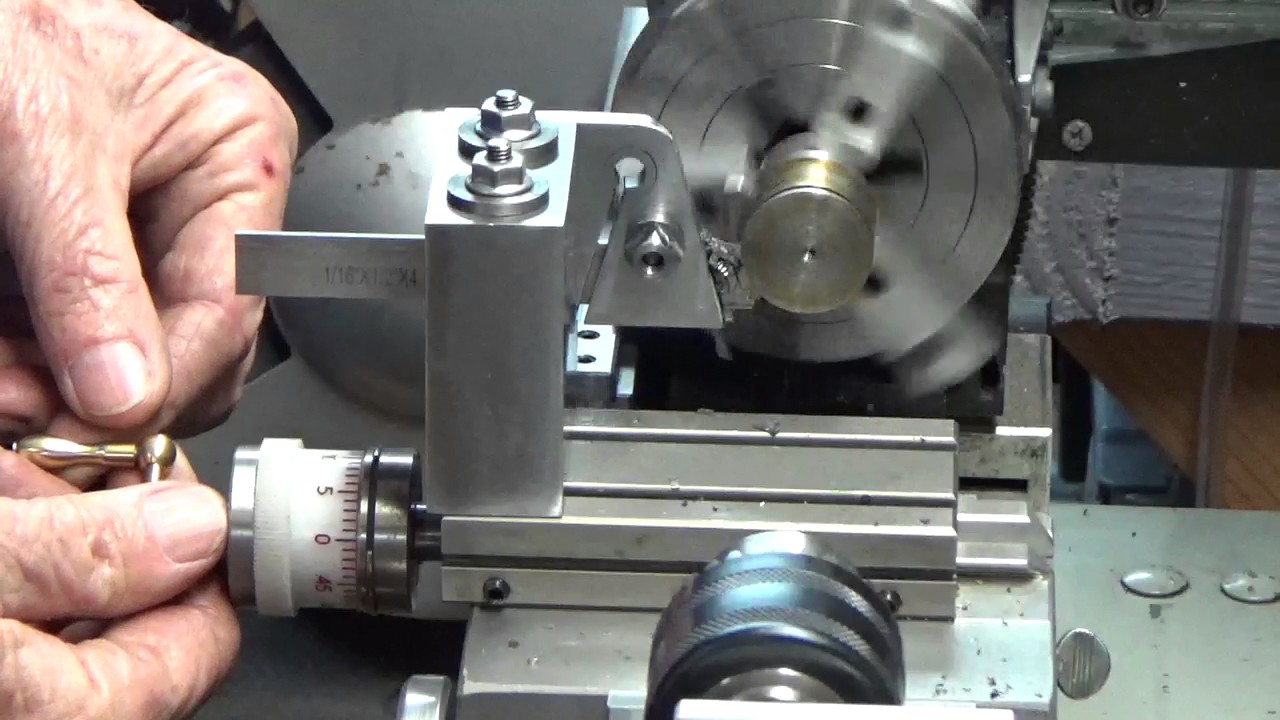

How To Sharpen A Metal Lathe Parting Tool

The grinding rest was tipped to give the required side clearance relief and the fence adjusted to give the side cutting edge angle.

How to sharpen a metal lathe parting tool. In general the method is to use either a grinder or belt sander and then finish with a hone. Maximize Cutting Tool Stiffness. A demonstration on how to sharpen a lathe parting tool.

If using an indexable part-off tool check that the cutting insert is in good condition. Used for roughing spindle stock only do NOT use on bowls. Turn the parting tool over and do the opposite side for the same amount of time.

Generally ground to 45 but 35 may work better on softer woods. Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds. Shaping skew chisels are pretty easy to do as well.

In general the method is to use either a grinder or belt sander and then finish with a hone. If you sharpen these using a V-pocket be careful the tip of the tool is above the centerline of the wheel. Next look up the typical angles for the workpiece material and then follow the steps in Figure A2.

The un-skewed cutting edge of the parting tools actually makes them much easer to sharpen. Trusted China Suppliers Verified by SGS. If using HSS parting blades grind andor hone the cutting edge to ensure its sharp.

Need to buy a new cutter now. Ad China Metal Lathe. Inspect the parting tool closely before using.