How To Manage A Cnc Machine Shop

It may look like a desk job type book but what it teaches fits very nicely with fabrication machine shop work.

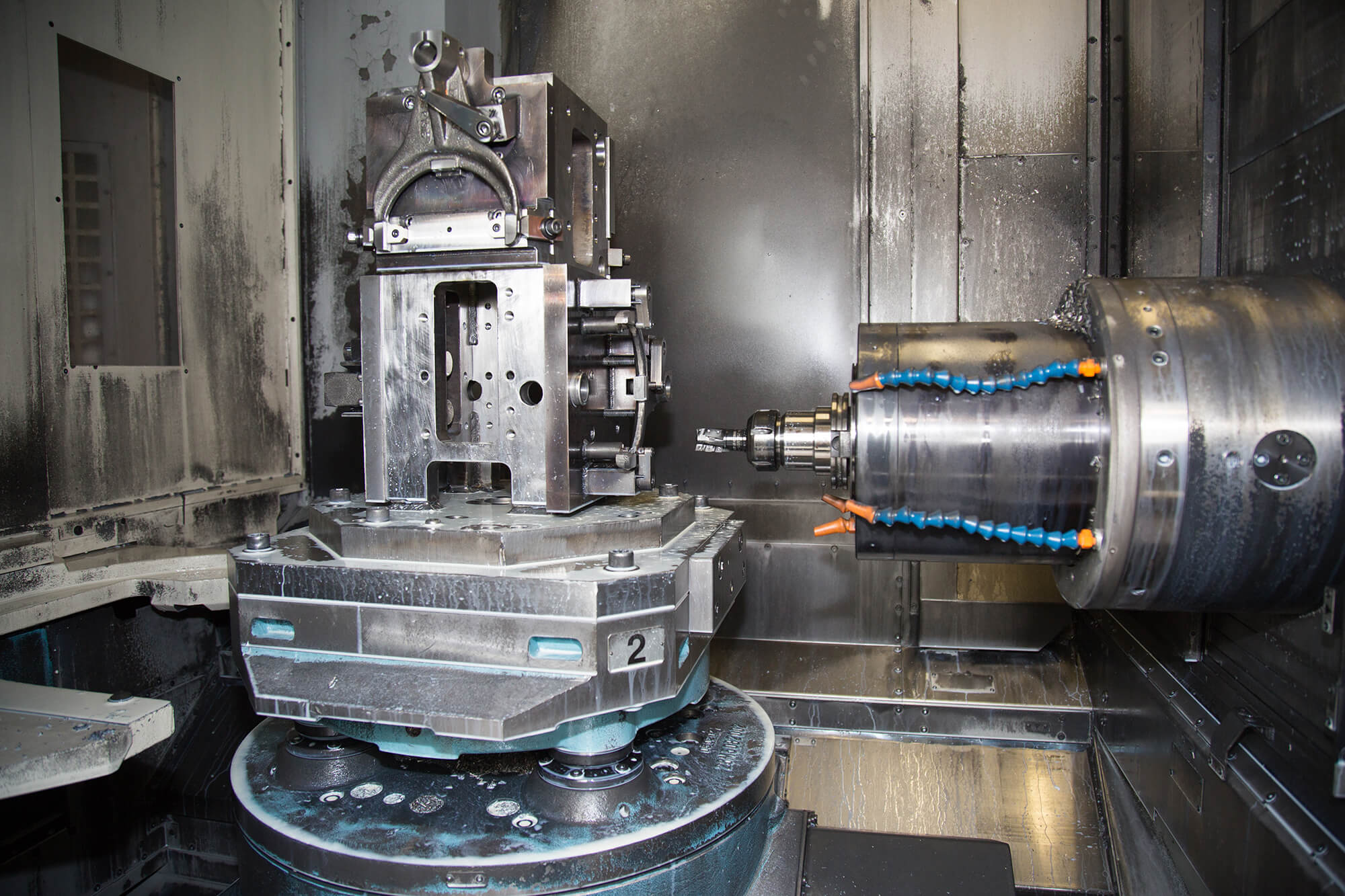

How to manage a cnc machine shop. Individually none of these changes is. Ive been dealing with a lot of change lately personally as well as professionally. It should go without saying that CNC people directly affect the productivity of the machine or machines on which they work.

Depending on the capabilities of the CNC machine shop they can concentrate on specific industries. Here are some tips and suggestions for small CNC machine shops to continue growing their businesses. Laurentian sniper1rfa fciron liked this post 05-06-2012 0930 PM 12.

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features. Because a companys productivity is directly related to the productivity of its CNC machine tools CNC people should be considered among the most important people in a company. Executive Editor Modern Machine Shop.

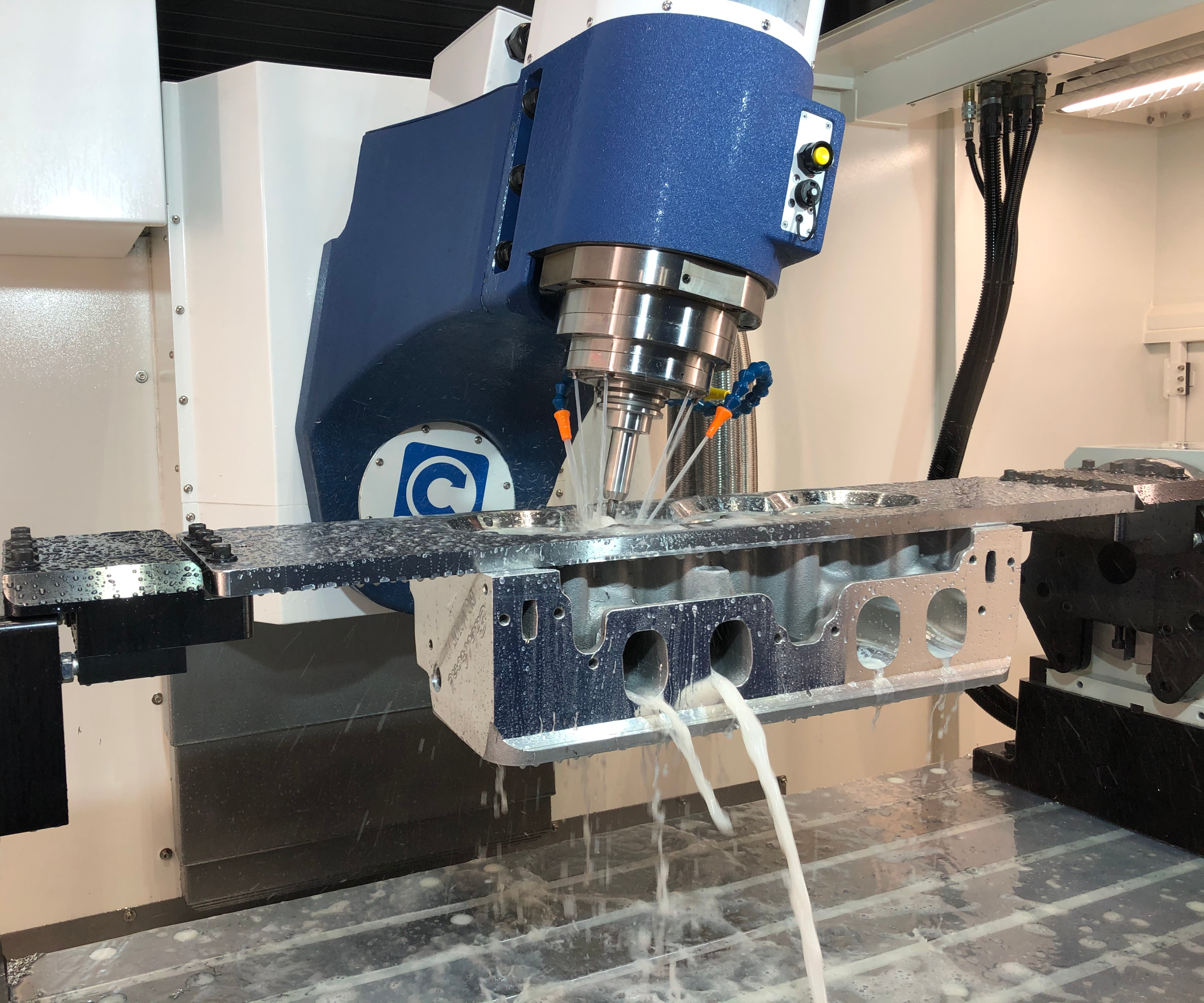

Presumably that data allows you to dramatically improve the efficiency of your shop floor. You can also use it to beef up your interview processes to make. How digitalization has changed the machine shop Computer Numerical Control became commonplace in the latter half of the 20th century changing machine shops forever.

Efficiency helps make production run smoothly and eliminates wasted time. Keeping the parts tools and production departments of a machine shop. Managers Must Understand CNC Responsibilities.

Automotive aerospace medical and. CNC Shop Owners and Managers use this as a guide for which skills are scarce. AB Machining and Fabrications 10.