How To Make Your Own Cnc Wood Router

But a few students made some simple modifications and improvements.

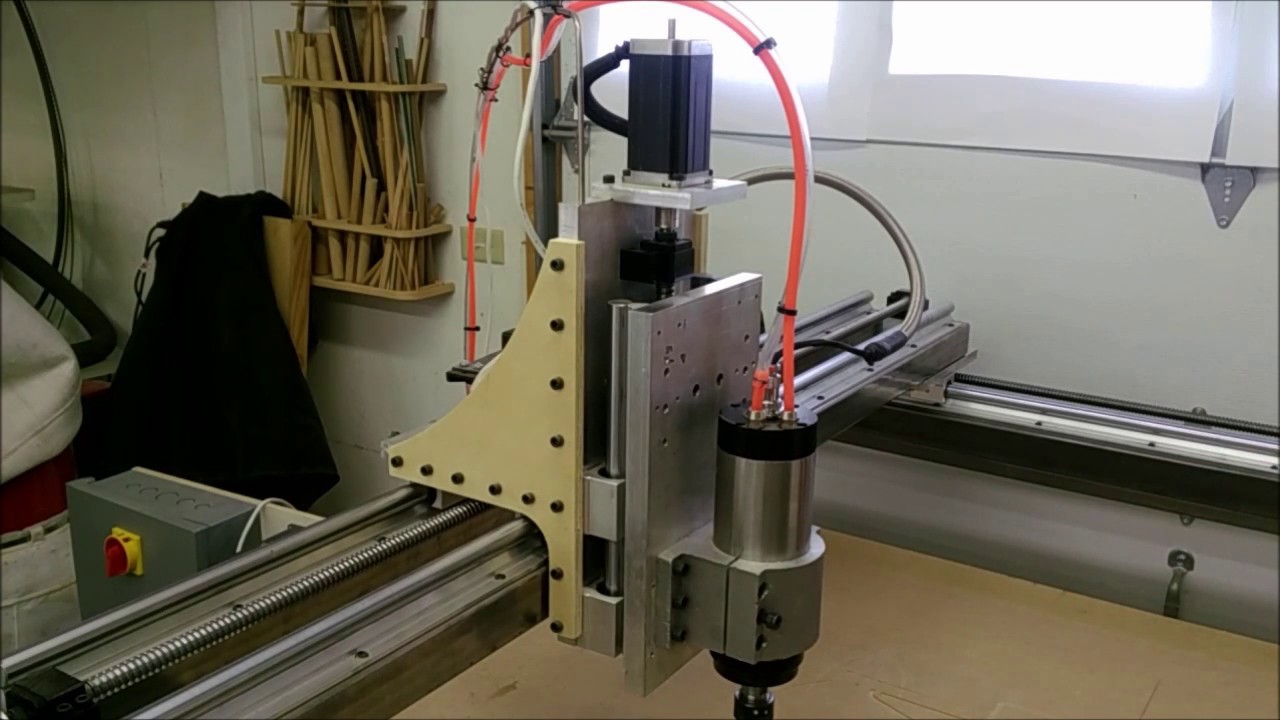

How to make your own cnc wood router. What kind of linear drive system will you use for each axis. 3 425 oz-in stepping motors 3 Drivers 30Amp 24-40 Volts 1-164 micro-stepping 1 36v 88a Power Supply 1 Breakout board I wired all the electronics up and added a few more features. CNC wood router can make many instruments like piano guitar violin and others.

With 20 inches wide the kinetic sculpture can run several hours by a single winding. These plans document all the steps I followed to make my DIY CNC Router. This is a very good router that can be built at a reasonable price using readily available materials.

A chop saw wood lathe drill and a drill press and finally a table saw nothing fancy but now with the CNC router he has a world of possibilities for projects. A set of metric and imperial hex keys 316 and 5. And yes you will need to treat all the measurement tools you use with utmost care.

For this example were going to look at a simple turtle jigsaw. Like many CNC router projects the wood needs to be flat and sanded down with grade 180-240 sandpaper. For homemade CNC routers drive screws are most commonly used.

Get the step-by-step plans for this Shop-Built CNC Router here. Below is a general outline of how a CNC router works and the steps required to create something using one. Learn your unique selling points.

Most importantly leverage your new and existing offline connections to get more clients. I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. Almost every CNC router hobbyist can create this wonderful project without the need for engraving metal parts.