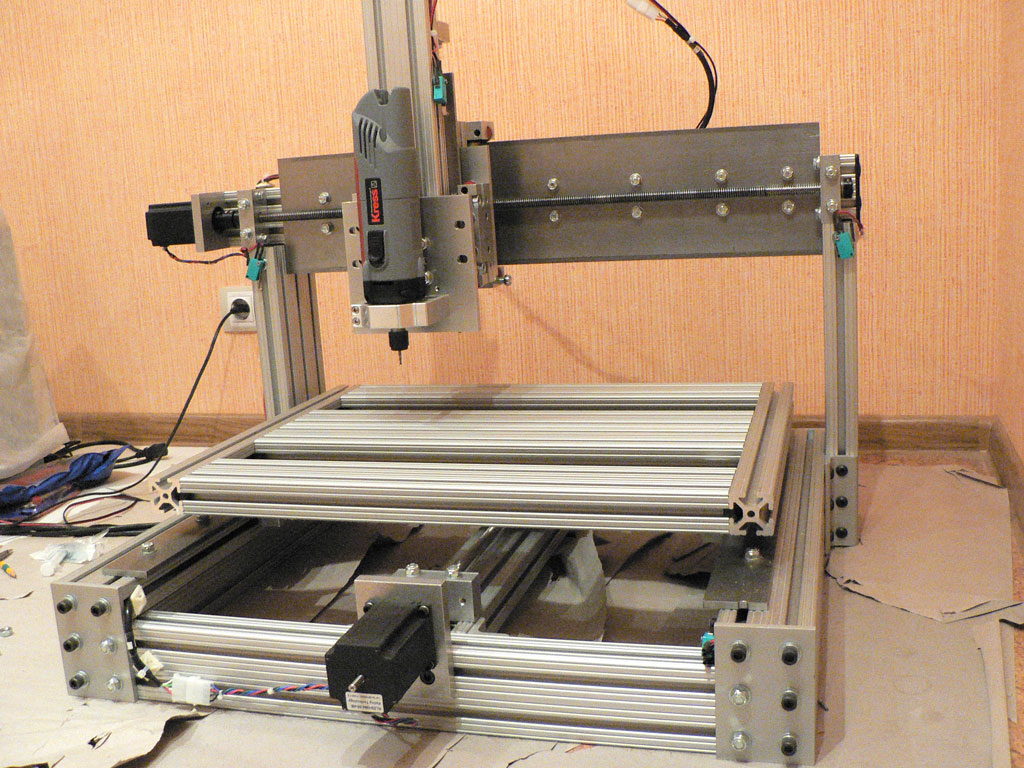

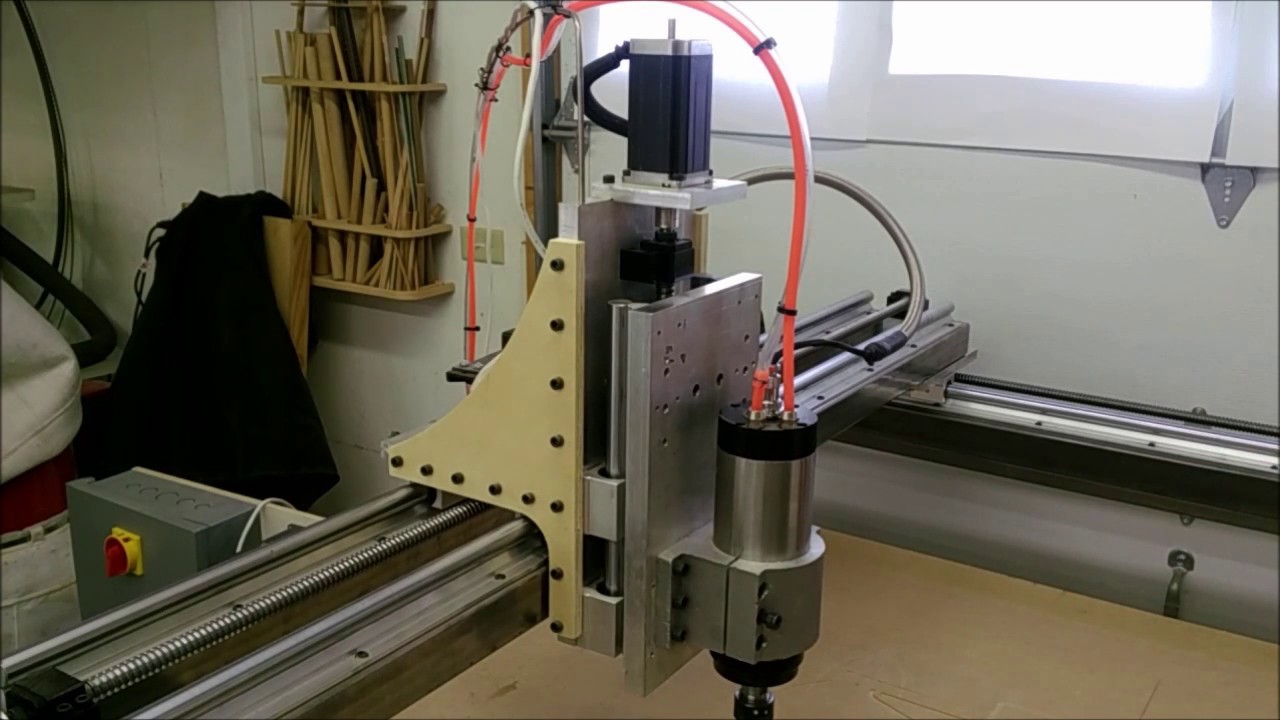

How To Make Wood Cnc Machine

Place your substrate under the drill head and turn on the CNCs vacuum to secure it in place.

How to make wood cnc machine. 85 Thread a 8 nut on each machine screw with a washer between the nut and the trolley. Add weights if necessary. Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis.

After I got the measurements of the CNC I designed it on Google SketchUp as well as a stand for it and a computer to operate it. Ad High Quality Wood Machine with Competitive Price. Put down paper to prevent glue from ruining the table.

Assemble the Torsion Base frame upside down on a VERY FLAT SURFACE. The very first step of making a CNC is PLANS. Start the CNC router and begin the program by pressing the Start or green button.

Discover how easily you can build a powerful Ultra-Precise CNC Woodworking Machine --Hobby versionDesktop versionProfessional wooden andor metal base ve. Install a small engraving bit onto the drill head. Make sure the frame is sitting flat and flush against the flat work surface.

Allow the Torsion Base core to dry thoroughly before the next step. 82 Attach four 2 machine screws to the motor mounting holes with washers against the faceplate 83 Thread on a 8 nut and a washer to each machine screw. Nevertheless the key steps to build your own CNC machine will generally be as follows.

Make sure that this bit is appropriate for the surface you are engraving on. Orient with the collar facing the motor and approximately 116 from the face plate. The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors.