How To Build A Cnc Woodworking Machine

Top 3D printing HP5210 MJF and 3D Systems 6100 - CNC with ultimate Hermle and Mazak 5axis.

How to build a cnc woodworking machine. Ad Unlimited access to Woodworking Machinery market reports on 180 countries. Ad Unlimited access to Woodworking Machinery market reports on 180 countries. The full form of CNC is computer numeric control.

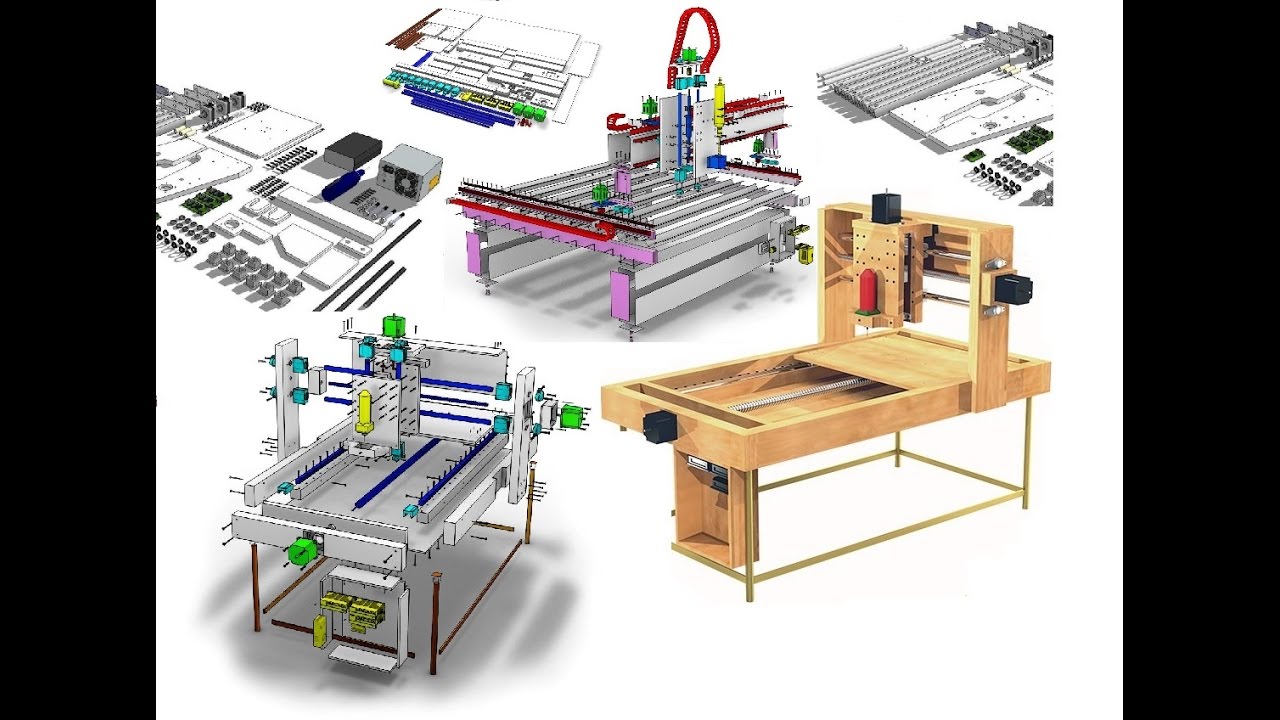

Tap into millions of market reports with one search. Quickly after the sketching phase came the CAD model. The Design and CAD Model.

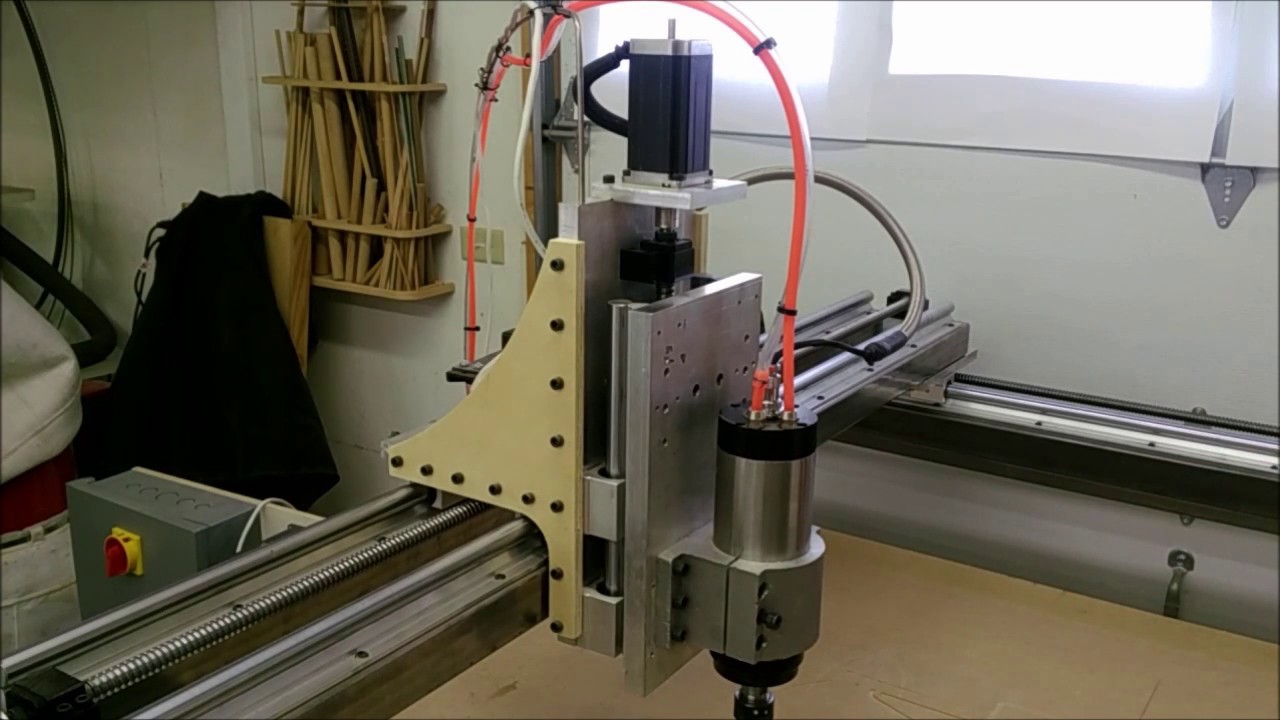

It all started with a proper design in my case a few sketches to get a good feeling for the dimensions and shape. Ad Your parts for less and without effort. The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors.

These plans document all the steps I followed to make my DIY CNC Router. CNC woodworking is an automated form of woodworking where a machine cuts shapes and engraves wood without any human interference after the initial setup. This is a very good router that can be built at a reasonable price using readily available materials.

I created my model in SolidWorks. Discover how easily you can build a powerful Ultra-Precise CNC Woodworking Machine --Hobby versionDesktop versionProfessional wooden andor metal base ve. Dont fret over how complicated that sounds it basically means a machine controlled by a computer.

I have no experien. If you plan to design your own machine I recommend a parametric CAD-modeling tool. Tap into millions of market reports with one search.