Explain The Different Types Of Cutting Tools

Following are the types of milling cutters that we use in different milling machines.

Explain the different types of cutting tools. Semi-automatic and automatic improves cutting room productivity and improves cutting accuracy. This cutter is developed from various types of materials. Cutting tools that are frequently used for metalworking include bandsaws broaches and drills.

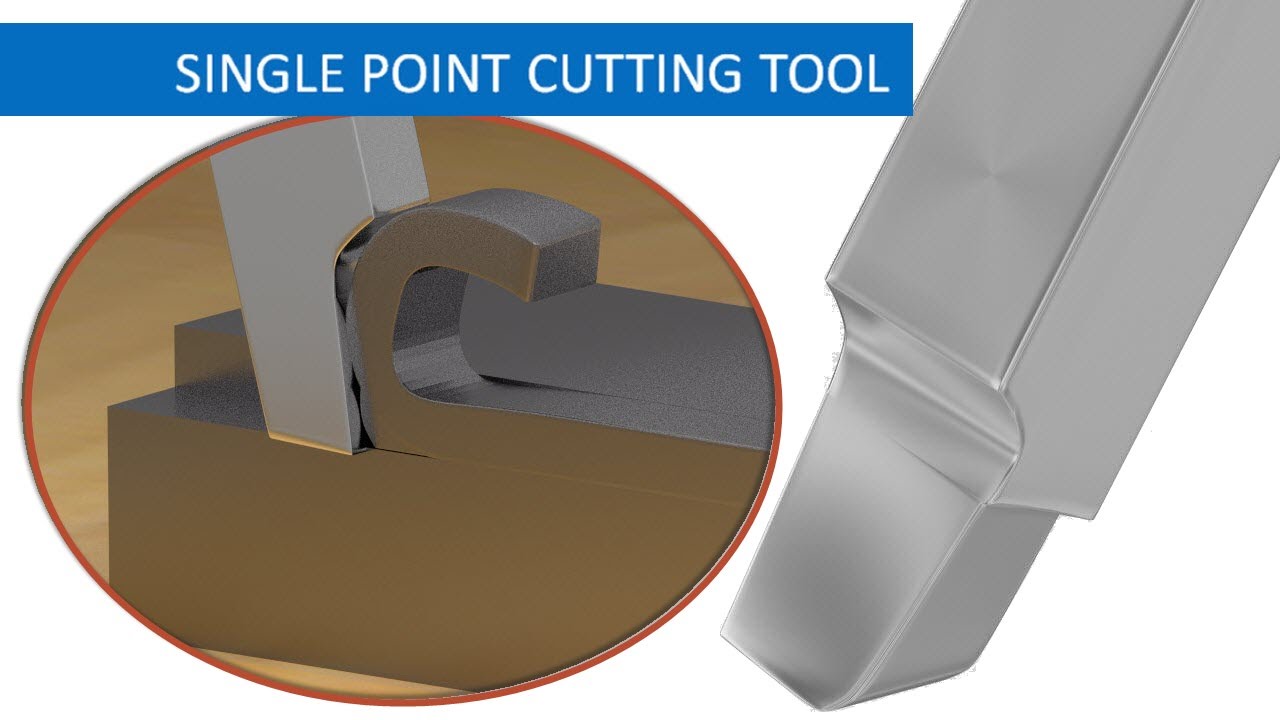

While some cutting tools require some type of human interaction to perform a function others might be completely computer operated. Other types of machining tools might include fly cutters and reamers. Some Cutters with Description 1.

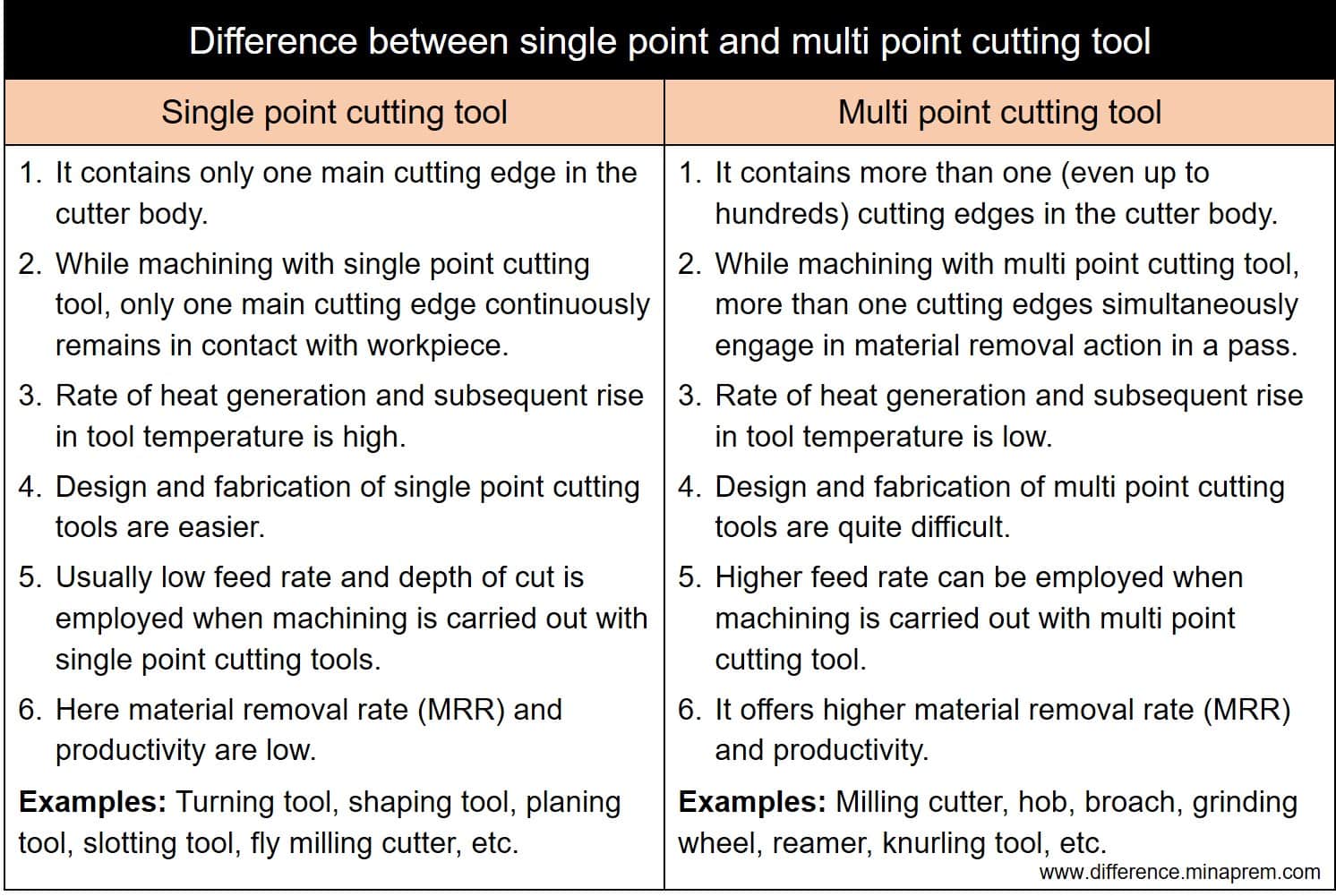

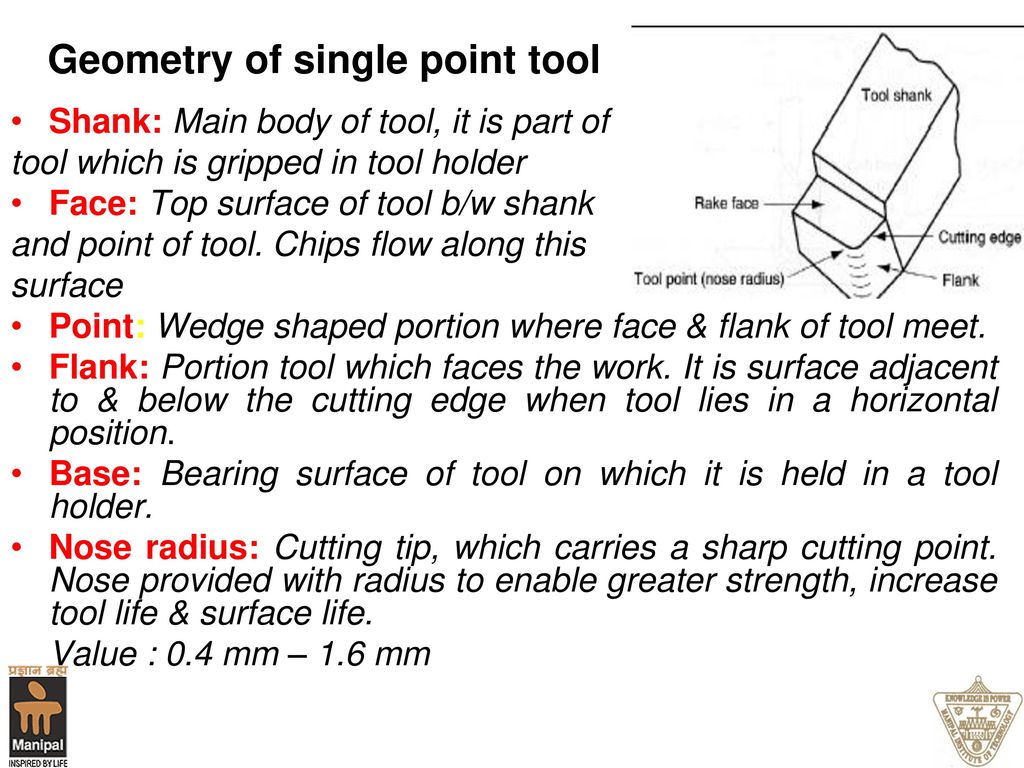

The blade will typically display wood bi-metal or metal. 29-3 Cutting Tools One of most important components in machining process Performance will determine efficiency of operation Two basic types excluding abrasives Single point and multi point Must have rake and clearance angles ground or formed on them. High Speed Steel HSS.

Forms of Tool Wear. Built-up edge means the adhesion of work material on the rake face of the cutting tool near the cutting edge. It occurs frequently while machining softer or ductile metals at lower cutting speeds.

Some other forms of tool wear are. The difference between end milling and face milling is that an end mill uses both the end and the sides of the cutter whereas face milling is used for horizontal cutting. A few common sizes are 38 34 1 and 1 38.

The cutting edge of the diamond tool is very sharp this is important for cutting chips with very small sections. Iii Cyclic Thermal and Mechanical Load Wear. These two portions of the cutting tool can be conjoined by following any process including clamping welding and so on.